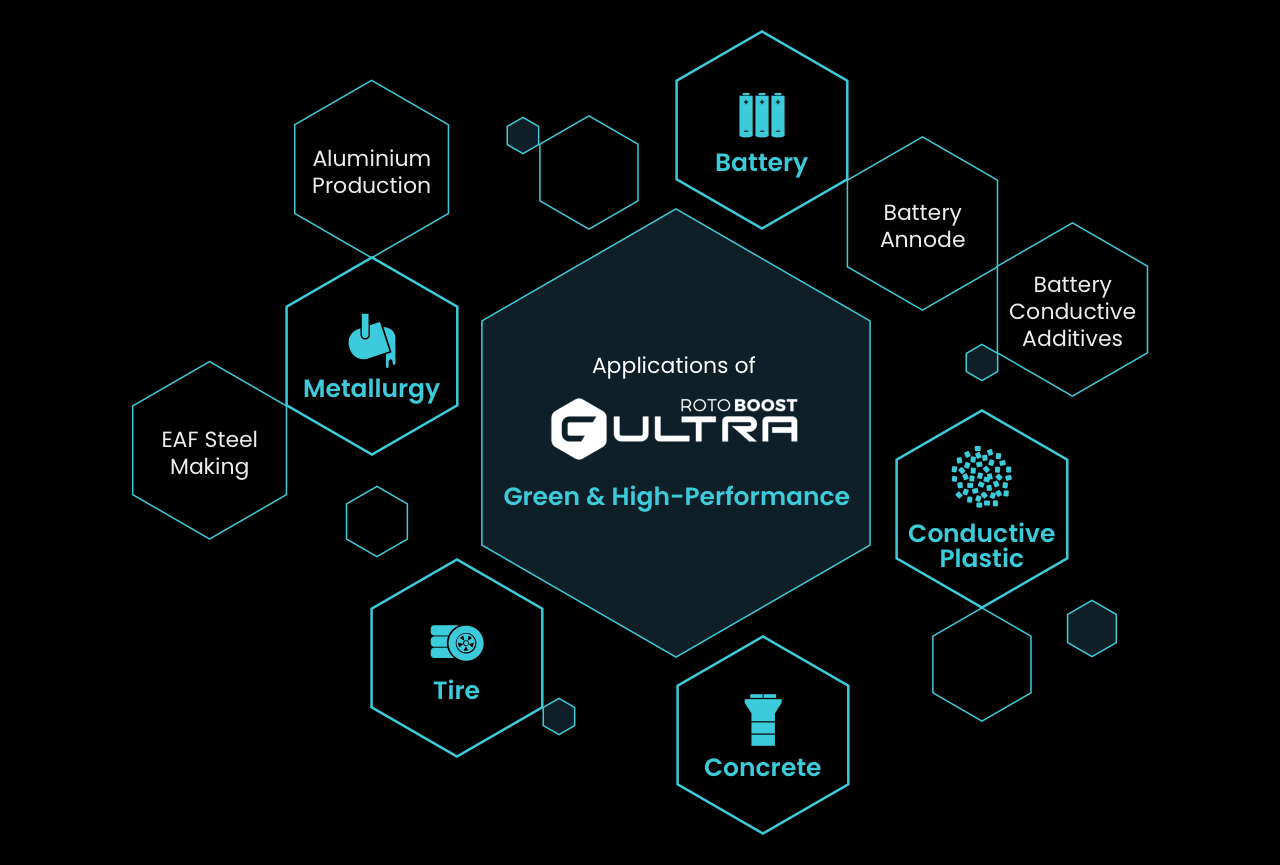

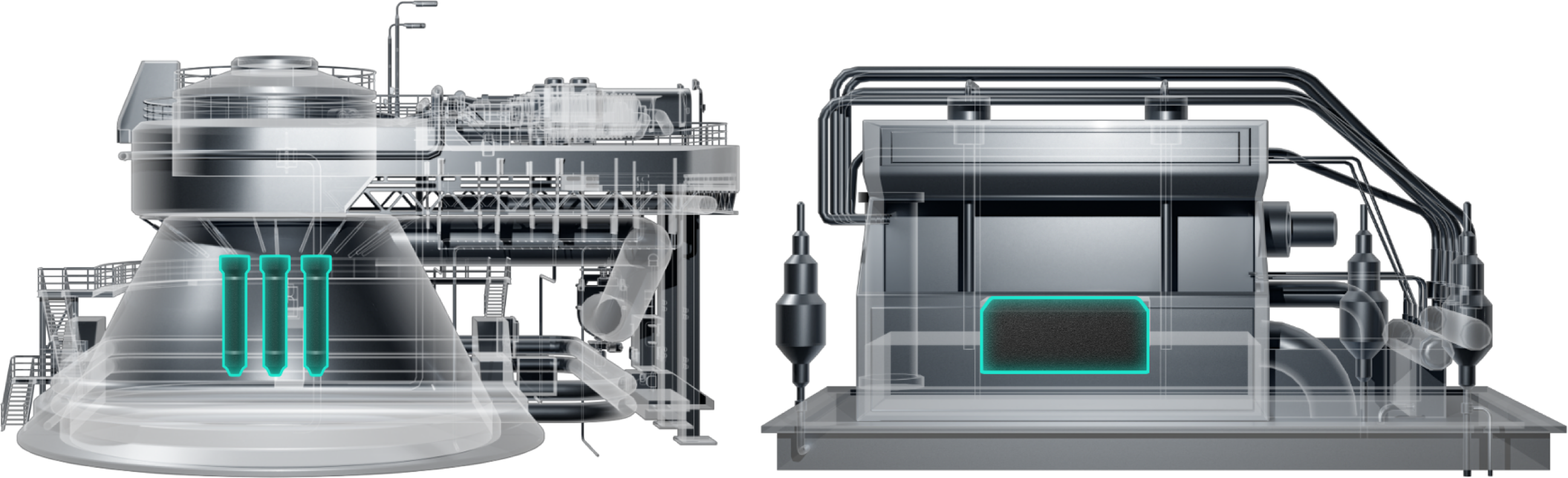

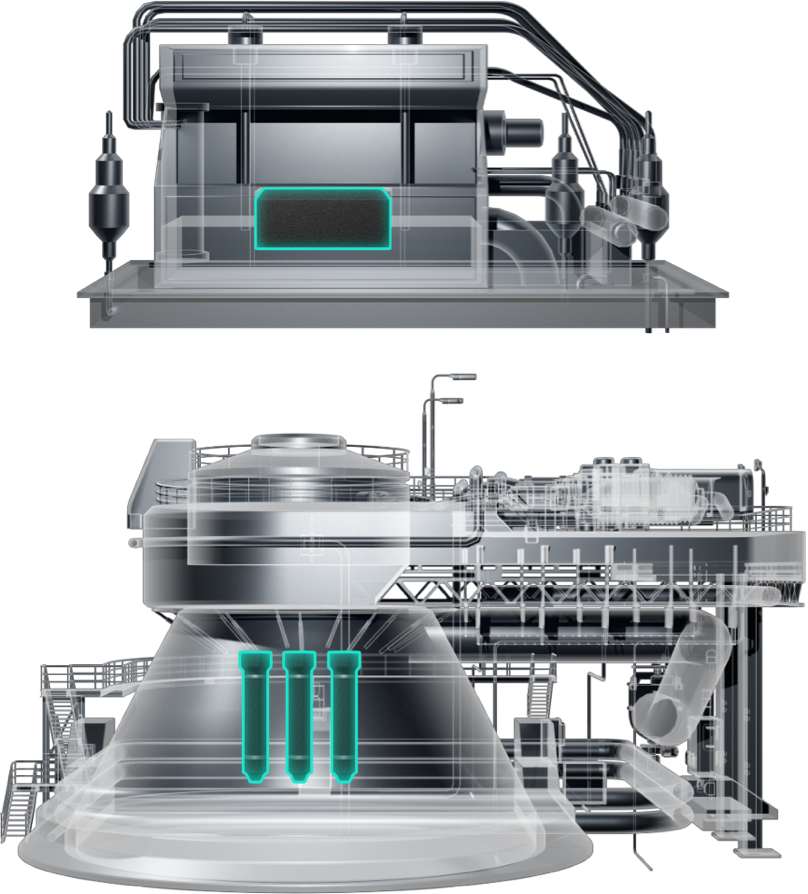

Leveraging a groundbreaking methane-splitting technology, the carbon generated by the ROTOBOOST TCD reactor is high-grade carbon in the form of Graphene Nanoplatelets (GNPs)—an advanced material additive that can be utilized in various downstream applications such as batteries, tires, concrete, and metallurgy.

CARBON

What is ROTOBOOST Carbon Product?

Applications

A New Generation Premium Green Carbon,

More than Alternatives

ROTOBOOST

Graphene

Nanoplatelets

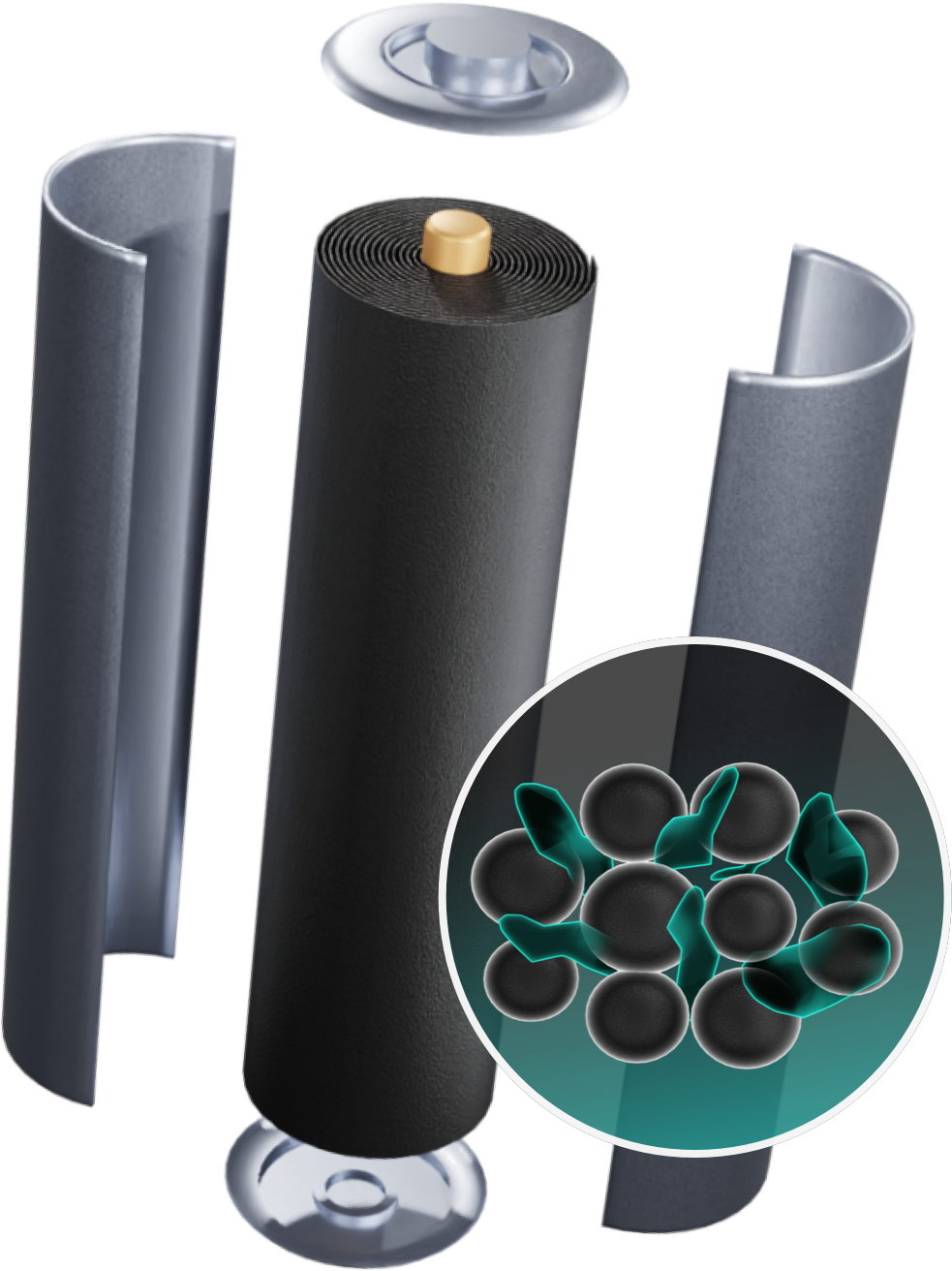

Born for NEXT GEN

Ultra-fast Charging Battery

Si-anode Battery

Solid-state Battery

New Generation Conductive Additives

Substituting few-layer graphene derived from natural graphite & a portion of CNTs

- Optimized production cost compared to commercially available GNPs

- Significant cradle-to-gate carbon emissions reduction compared to graphene products derived from natural graphite

- Comparable enhancement to that of few-layer graphene

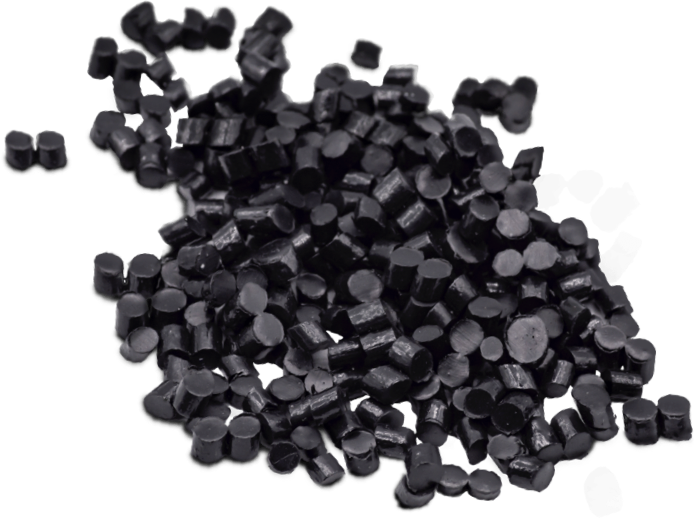

Multifunctional Conductive Filler

Power battery casing

Electromagnetic Interference (EMI) Shielding

High Voltage Cable Semiconducting Shield Material

- Offer ultra-high purity and stability, making them ideal for demanding applications in medical, electronics, and automotive industries.

- Multi-performance enhancement by simultaneously improving electrical conductivity, mechanical strength, heat resistance, and barrier properties.

- Enhance processability and precision by reducing viscosity, minimizing warpage, and ensuring superior surface quality in final products.

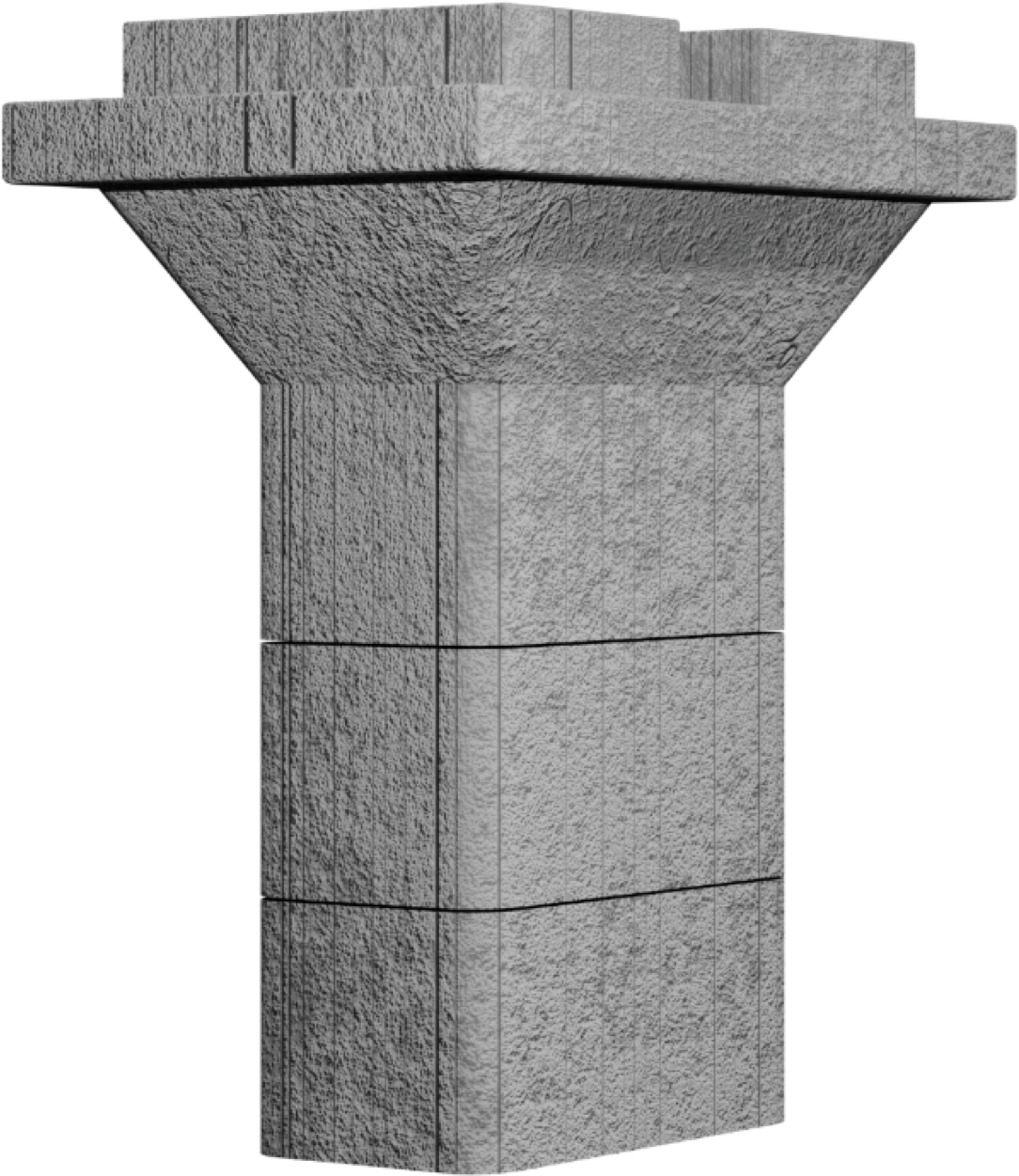

Superior

Performance

to Meet the Demands of Various Specialized Scenarios

Marine Environments

Energy Harvesting

Road/Bridge De-icing

Electromagnetic Shielding

Additives for High-Performance & Green Concrete

- Enhanced mechanical properties

- Thermal/electrical conductivity

- Significantly lower cost than traditionally-produced graphene

- Reducing cradle-to-gate carbon footprint

Filler in

Composites

Tensile Strength

Tribological Performance

Heat Dissipation

Substituting carbon black for tire reinforcement additive

- Enhance mechanical and anti-aging properties

- Better performance than traditional and recycled carbon blacks

- Rubber composite property enhancement on tensile strength, tribological performance and heat dissipation

- Cutting cradle-to-gate carbon footprint at scale

Facilitating EAF Steelmaking and Green Aluminum Production

Substituting coal & coke for graphite electrode and pre-baked anode

- 2X more conductive

Related News

Baowu—World’s Largest Steelmaker—Teams with ROTOBOOST to Industrialize Natural Gas Splitting for Green Steel at Scale

Government-sponsored BF–MOST (Business Finland × China MOST) China–Finland project to deliver on-site low-carbon hydrogen and high-value solid carbon for steel and aluminum—enabling true industrial decarbonization and value creation.

ROTOBOOST Awarded World’s First TÜV SÜD Certification for Low-Carbon Hydrogen and Carbon Products via Methane Pyrolysis

June 6, ROTOBOOST has become the world’s first company in the methane pyrolysis field to receive TÜV SÜD’s certification for the full lifecycle carbon footprint of hydrogen and carbon products.